Wie stellt eine moderne Transformator-Folienwickelmaschine eine hochpräzise Lagenausrichtung und Zugkraftregelung sicher?

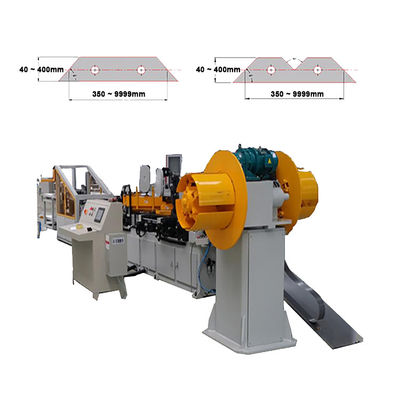

Die Herstellung hochwertiger folienbewickelter Transformatoren hängt vollständig von der Präzision und Konsistenz des Wickelprozesses ab. Da Folienwicklungen von Natur aus kurz und breit sind, können selbst kleine Fehlausrichtungen oder inkonsistente Zugkräfte zu katastrophalen Ausfällen führen, einschließlich interner Kurzschlüsse, ungleichmäßiger Stromverteilung oder strukturellem Zusammenbruch unter Fehlerbedingungen. Die grundlegende Frage für Hersteller lautet: Wie setzt eine moderne, automatisierte Transformator-Folienwickelmaschine fortschrittliche Technologie ein, um die hochpräzise Lagenausrichtung und die konsistente Zugkraftregelung zu gewährleisten, die für die Spulenintegrität erforderlich sind?

Um Perfektion beim Folienwickeln zu erreichen, muss die Steuerung von zwei Schlüsselmaterialien – der Leiterfolie und der Zwischenlagenisolierung – gleichzeitig und über breite Breiten beherrscht werden.

Hochpräzise Lagenausrichtung (Kantengeführung):

Der kritischste Ausrichtungsparameter ist die Aufrechterhaltung der exakten axialen Position der Folienstreifen. Selbst eine Fehlausrichtung von Bruchteilen eines Millimeters kann scharfe Kanten oder Lücken erzeugen, die die Isolierung schwächen und zu Teilentladungen oder Kurzschlüssen führen. Moderne Folienwickelmaschinen verwenden ausgeklügelte Kantengeführungs-Systeme, um natürlichen Schwankungen in der gelieferten Folienbreite und dem mechanischen Rundlauf der Maschinenkomponenten entgegenzuwirken.

Diese Systeme verwenden berührungslose Sensoren, typischerweise hochauflösende Laserpositionssensoren oder Ultraschallsensoren, um die genaue Kantenposition der Leiterfolie kontinuierlich zu überwachen, während sie auf den Dorn aufgebracht wird. Die Sensoren speisen Daten in Echtzeit an eine Hochgeschwindigkeits-SPS (Speicherprogrammierbare Steuerung). Diese Steuerung wiederum steuert Präzisions-Linearaktuatoren, um sofortige, mikroskopische seitliche Korrekturen an der Folienabwickelvorrichtung vorzunehmen. Dieser geschlossene Regelkreismechanismus stellt sicher, dass die Folienkante während des gesamten Wickelzyklus innerhalb der spezifizierten Toleranz (oft weniger als $pm 0,1 text{mm}$) bleibt, wodurch perfekt glatte und präzise Spulenkanten gewährleistet werden, die für die langfristige dielektrische Leistung unerlässlich sind.

Konsistente Zugkraftregelung:

Die Aufrechterhaltung der korrekten Wickelspannung ist ebenso wichtig. Wenn die Spannung zu hoch ist, kann sich die Folie verjüngen, wodurch der Querschnitt verringert und der Leiter geschwächt wird, oder die Isolierung kann übermäßig gedehnt und beschädigt werden. Wenn die Spannung zu niedrig ist, ist die Wicklung weich, was zu einer schlechten mechanischen Stabilität führt, die Bewegungen und Ausfälle unter Kurzschlusskräften zulassen kann.

Moderne Folienwickelmaschinen verwenden ausgeklügelte elektronische Zugkraftregelungssysteme, die über einfache mechanische Bremsen hinausgehen. Diese Systeme umfassen typischerweise:

Tänzerarm-Rückmeldung: Ein gewichteter oder luftgedämpfter Tänzerarm fährt auf dem Leiter- und Isoliermaterial. Die Position dieses Arms liefert einen physischen Echtzeit-Indikator für die Spannung und die Vorschubgeschwindigkeit des Materials.

Wägezellentechnologie: Hochpräzise Wägezellen sind oft direkt in den Materialpfad integriert, um eine direkte, elektronische Messung der tatsächlichen Kraft (Zugkraft) zu liefern, die auf den Folienstreifen ausgeübt wird.

Drehmomentregelung im geschlossenen Regelkreis: Die Wägezellen- oder Tänzerarmdaten werden an einen speziellen Zugkraftregelantrieb zurückgeführt. Dieser Antrieb passt dann das Drehmoment des Folienabwickelmotors elektronisch an. Im Gegensatz zu mechanischen Bremsen, die aufgrund von Reibung und Verschleiß inkonsistent sein können, bietet die elektronische Drehmomentregelung sanfte, sofortige und wiederholbare Anpassungen über den gesamten Drehzahlbereich und hält die Spannung innerhalb einer minimalen Toleranz vom Beginn bis zum Ende der Spule.

Darüber hinaus muss die Maschine die sich ändernden Eigenschaften der Folienspule verwalten – insbesondere den abnehmenden Durchmesser und die zunehmende Drehzahl, die erforderlich sind, um eine konstante lineare Geschwindigkeit aufrechtzuerhalten. Das Zugkraftregelungssystem muss diese Trägheitsänderung dynamisch berechnen und anpassen, um sicherzustellen, dass die Spannung unabhängig vom aktuellen Durchmesser der Spule konstant bleibt.

Durch die nahtlose Integration von berührungsloser Lasermessung zur Kantengeführung mit ausgeklügelten elektronischen Wägezellen zur Zugkraftregelung erreicht eine moderne Transformator-Folienwickelmaschine die erforderliche Präzision und Konsistenz. Dieses Maß an automatisierter Steuerung minimiert die Abhängigkeit vom Bediener, maximiert die Materialausnutzung und stellt vor allem sicher, dass jede produzierte Spule die gleichmäßige Struktur und mechanische Integrität aufweist, die für den langfristigen, hocheffizienten Transformatorbetrieb erforderlich sind.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!